Investment casting

Castech Foundries Pvt. Ltd. manufactures custom investment castings using the lost wax and lost foam processes. The company was founded in 1994 and has a capacity of 150 tons per month. Both low-alloy steels and high-alloy stainless steels are cast. Castech is ISO 9001:2015m ISO 14001:2015 and BS OHSAS 18001:2007 certified. In addition, Castech has product approvals according to NORSOK, PED, AD2000 and IBR.

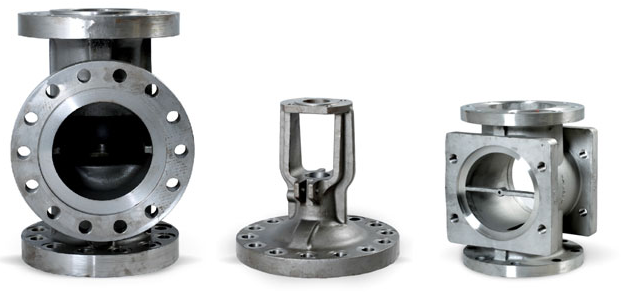

Castech's capabilities include the manufacture of parts for the instrument making, general engineering, power and oil & gas sectors. The focus is on the manufacture of the following parts: ball valves, control valves, check valves, gas valves, butterfly valves and pumps. Parts with a weight of up to 80kg and a maximum size of 500mm x 500mm x 350mm are manufactured using the lost wax process. Parts with a weight of 20kg to a maximum of 300kg and a size of 1000mm x 1000mm x 800mm are manufactured using the lost foam process.

Manufacturing process:

Lost Wax, Lost Foam

Applications:

Instrumentation, General Engineering, Energy Sector, Oil and Gas

Products:

ball valves, butterfly valves, gate valves, globe valves, check valves, machined products, plug & slight glass valve and pumps

Materials:

Carbon Steel & Low Alloys - Austenitic / Super Austenitic Alloys, Duplex & Super Duplex Alloys, Nickle Base Alloys, Heat Resistance Alloys, Hardenable Alloys

Weight:

| Lost Wax | few grams up to 80kg | |

| Lost Foam | 20kg up to 300kg |

Dimensions:

| Lost Wax | 500mm x 500mm x 350mm | |

| Lost Foam | 1000mm x 1000mm x 800mm |

Certifications:

Well known IBR, ISO 9001, ISO 14001, TÜV AD 2000 W0, PED, BS OHASAS 18001, NORSOK

Classification Societies:

All national and international

Delivery versions:

According to the customer's wish in raw, pre machined , finish machined